Nanoplazz — revolution in the fight against climate change

Product selectivity

98%

En

Plant energy efficiency

95%

Plant conversion rate

98%

Revolutionary nanosecond pulsed plasma technology transforming greenhouse gases into valuable products

Innovating carbon conversion for a greener future

About us

Nanoplazz is a revolutionary

technology to convert greenhouse gases into valuable products and fight climate change.

technology to convert greenhouse gases into valuable products and fight climate change.

Nowadays, critical level of greenhouse emissions is one of the biggest environmental challenges.

We offer you a presentation video in order to introduce our technology in details

Main features of our methane and CO conversion system

2

Features

Сontrolled pulsed plasma

dynamic plasma filament manipulation

Heat recuperation

heat remaining after reaction can be reused

Ultra-fast quenching

no reverse reactions, no by-products

Heat efficiency

power supply and electrodes regulation prevents long-term electrical discharge

High selectivity

prevention of by-products and reverse reactions formation

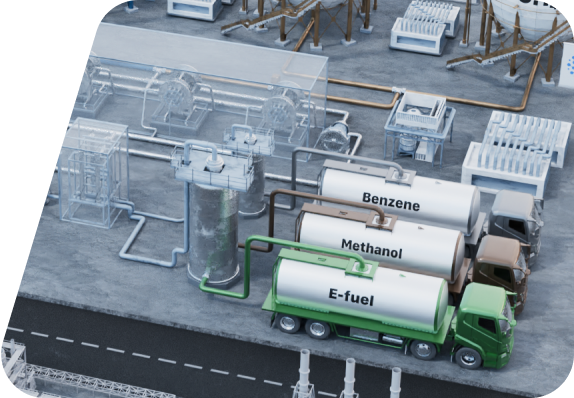

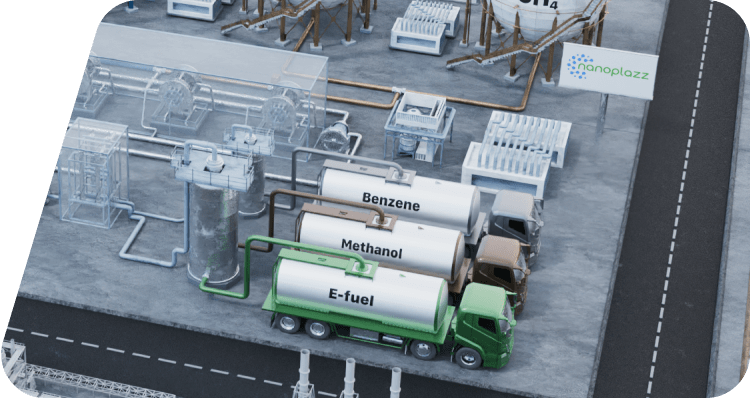

Products

Valuable final products

Benzene

Hydrogen

Acetylene

CO based E-fuel

Carbon credits (CO2&CH4 utilization)

Mission

Our project's

mission

Reducing greenhouse gas emissions

Economically rational greenhouse emissions monetization

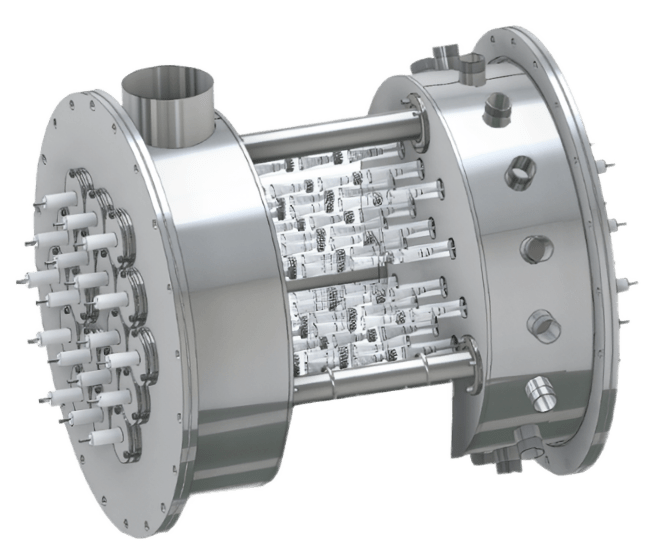

Nanoplazz pulsed plasma reactor

Technology

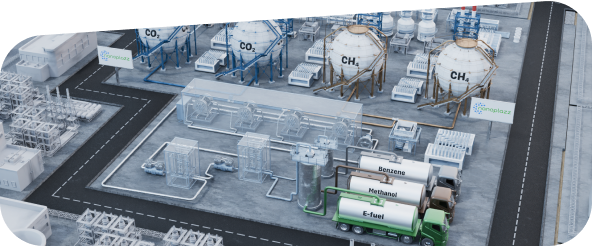

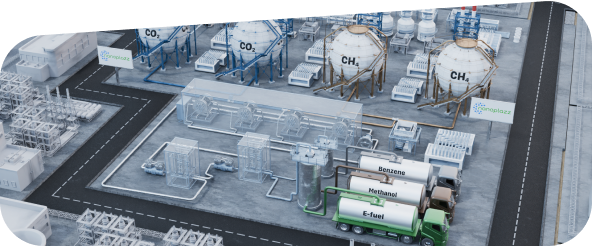

Our system includes reactor, power supply unit, control system and supporting devices regulating gas flow through the reactor

The feedstock enters the reactor, where pulses of non-equilibrium plasma are generated with high temperatures reaching ten thousand degrees Celsius. Such conditions decompose the initial carbon dioxide and methane into atoms and radicals, which further unite to form the final products — hydrogen, acetylene, carbon monoxide.

Advantages

Nanoseconds for reaction

Low-temperature reactor output

Low energy consumption

High reliability and extended lifetime

Modular & scalable

High fault tolerance

High voltage, low current

No soot formation

The process is based

on 2 chemical reactions

Process

CH4 conversion

CO2 conservation assisted by methane

СH4 conversion rate: 65%

CO2 conversion rate: 50%

C2H2 purity > 70%

CO purity > 95%

CO energy cost: ≤ 2 kWh/m3

Conversion rate

C2H2 energy cost: ≤10 kWh/m3

Purity

Energy cost

Conversion rate

Purity

Energy cost

Industrial

Pulsed plasma

reactor benefits

The reactor parameters are selected in order to reduce the number of reverse reactions and efficiently recuperate energy

Plasma reactor unit

Efficient gas conversion

Gas separation unit

Selective product separation

Per 1 ton of benzene:

Energy for plasma: 12 MWh

CH4 consumption: 1.6 ton

Energy for plasma: 12 MWh

CH4 consumption: 1.6 ton

Per 1 ton of Synfuel:

Energy for plasma: 16 MWh

CO2 consumption: 0.8 ton

CH4 consumption: 0.9

Energy for plasma: 16 MWh

CO2 consumption: 0.8 ton

CH4 consumption: 0.9

Source of CO2 and CH4

Feedstock

Plasma reactor unit

Efficient gas conversion

Gas separation unit

Selective product separation

Source of CO2 and CH4

Feedstock

Per 1 ton of benzene:

Energy for plasma: 12 MWh

CH4 consumption: 1.6 ton

Energy for plasma: 12 MWh

CH4 consumption: 1.6 ton

Per 1 ton of Synfuel:

Energy for plasma: 16 MWh

CO2 consumption: 0.8 ton

CH4 consumption: 0.9

Energy for plasma: 16 MWh

CO2 consumption: 0.8 ton

CH4 consumption: 0.9

Our innovative technology finds its application

Partnership

Since April 2023, we've been collaborating with industry-leading companies to introduce our innovative technology to them, uncovering a strong demand for green, cutting-edge solutions

Investment fund

Production of high-margin products (acetylene-based indole production)

- MoU signed

Polymer manufacturer

Obtaining benzene as a feedstock

- MoU signed

- Joint technology development agreement is being signed

- Joint task team assigned

Oil&Gas company

Monetizing excess methane

& reducing carbon emissions fines

& reducing carbon emissions fines

- Comfort letter issued

- Joint task team assigned

Collaborating with us

Contact us

is your way to profitably recycle greenhouse emissions and to provide a green legacy for our Planet!

Drive innovation, deliver sustainability